Why Pressure Tanks Matter

Pressure tanks store a cushion of air to absorb pressure fluctuations, reduce pump cycling, and maintain stable output. Proper sizing and installation are critical for system efficiency.

Types of Pressure Tanks

- Hydropneumatic Tanks: Bladder or diaphragm tanks for potable water systems.

- Expansion Tanks: For closed-loop heating systems to absorb thermal expansion.

- Pulsation Dampeners: To smooth pulsations in high-flow applications.

Pre-Installation Planning

- System analysis to determine optimum tank volume and pressure settings.

- Verification of pump capacity and electrical supply.

- Site preparation including mounting location and piping layout.

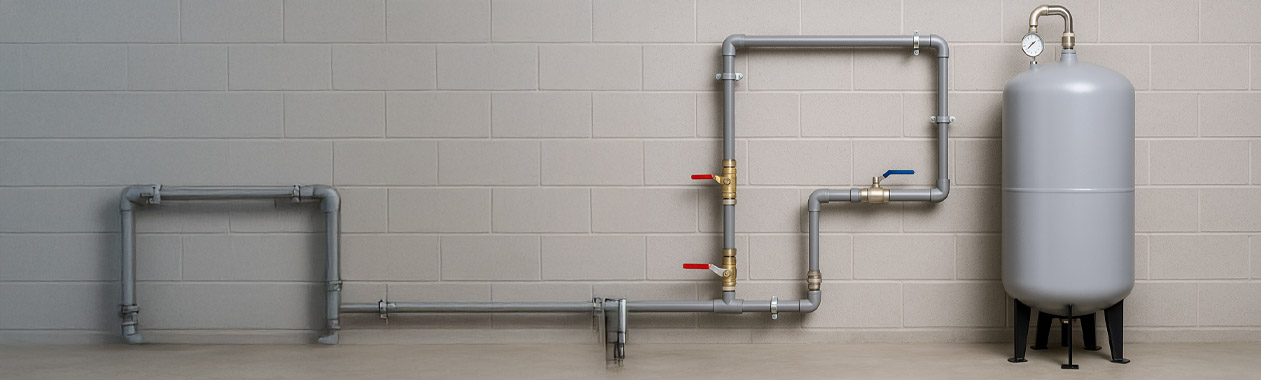

Installation Procedure

- Mount tank securely to foundation or support stand.

- Connect inlet and outlet piping with isolation valves and pressure gauges.

- Adjust pre-charge pressure with air compressor to match system cut-in pressure.

- Integrate with control panel and set up pressure switches or transducers.

- Commissioning: test for leaks, monitor pressure cycles, and optimize settings.

Maintenance & Support

Our AMC plans include annual inspections, air charge checks, diaphragm/bladder replacement, and performance testing to ensure your pressure tank operates flawlessly.

Case Study

Installed a 200-liter hydropneumatic tank in a commercial building, reducing pump cycling by 50% and ensuring uninterrupted water supply to 50 apartments.

Frequently Asked Questions

- How often should I check tank pressure?

- We recommend quarterly inspections and air charge checks every 6 months.

- Can I install on my own?

- Professional installation ensures correct sizing and compliance with safety standards.